GENERATOR OUTPUT CONTROL

The main characteristic of the plain shunt

connected generator is that the output rises with increasing speed and if this

were uncontrolled irreparable damage would be caused to the generator and the

battery.

The systems currently used to control this

output are:

1. Compensated Voltage Control

2. Current-Voltage Control.

COMPENSATED

VOLTAGE CONTROL

It will be remembered that battery terminal

voltage varies with the state of charge, so if we control the voltage of the

generator at a specific level i.e. terminal voltage of a fully charged battery,

then the pressure differential between the generator and the battery will be

greatest when the battery is discharged allowing a high current to flow,

reducing as the battery becomes charged, until theoretically the pressures will

be equal and no current will flow,

If the battery was in a very low state of

charge, the current flow could be extremely high, most probably higher than the

generator could safely deliver, and the armature windings would be damaged.

Because of this, we have to use some form of COMPENSATION.

At low speeds, the generator output is less

than the battery voltage, so an automatic switch or cut-out is incorporated in

the circuit to prevent the battery being discharged through the armature

winding.

COMPENSATED

VOLTAGE CONTROL

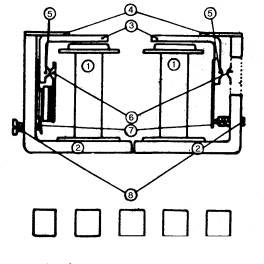

RB.

106 LUCAS

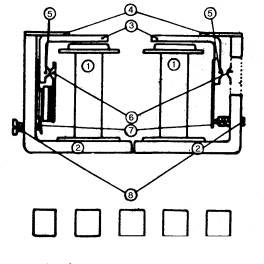

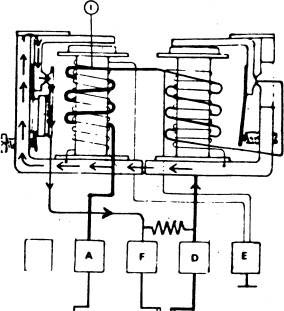

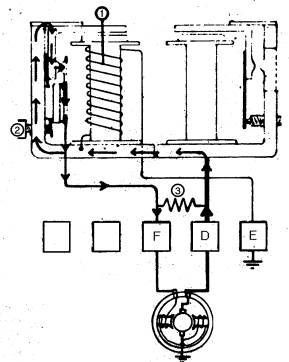

Fig. 1

Fig.

1 shows a section through the RB106, and from this we can trace its build-up

and operation.

Two

soft iron cores (Fig. 1-1) are mounted

on an 'L' shaped soft iron frame (Fig. 1-2). (For simplicity, the frame

is shown in two parts)

An. ‘L’ shaped armature (Fig. 1-3) carrying a contact Point (Fig. 1-5) is mounted above each core on a spring

blade (Fig. 1-4).

This

contact is so positioned to line up with a stationary contact (Fig. 1-6)

insulated from the frame. Another spring blade (Fig. 1-7) is attached to the vertical arm and lines up with fine

threaded screws (Fig. 1-8), which

can be adjusted to vary the force required to move the armature.

You will see that the L/H points are held

in the closed position by the spring blade (Voltage Regulator) and the R/H

points are held open by the spring blade (Cut-out).

REGULATOR

POINTS

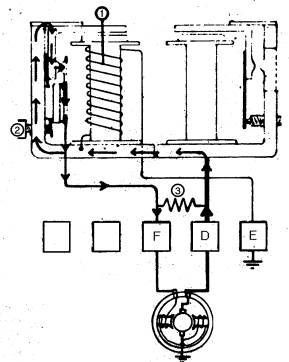

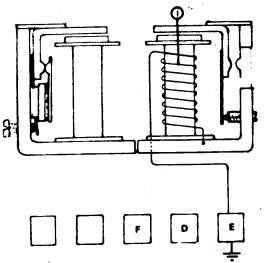

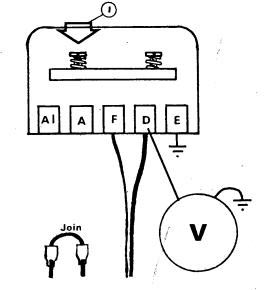

Fig. 2

In Fig. 2 we can see the circuit from generator terminal (D) to the

frame, through the regulator contacts, and back to the generator terminal (F);

this means the generator field is connected and there will be an output from

the generator. To regulate this, a shunt coil (Fig. 2-1) is wound round

the core with one end connected to the frame (dynamo potential) and the other

to earth. When current flows through this coil, magnetism tends to pull the

armature down against the spring; at a given voltage it will overcome the

spring and the O & F connection will be broken. Because the generator

output now falls, current through the shunt coil will also fall, reducing the

magnetism until spring tension closes the contacts again. This cycle is

repeated approximately 60 - 100 times per second, which gives a steady control

over generator voltage.

The controlled voltage can

easily be set to the required level by using the screw (Fig. 2-2) to adjust the spring tension. If we break the circuit

when the field current is passing

considerable arcing will take place across the regulator points, also the

generator field will be slow to collapse. To prevent this, a resistance (Fig. 2-3) is placed in parallel with

the points.

CUT-OUT

POINTS

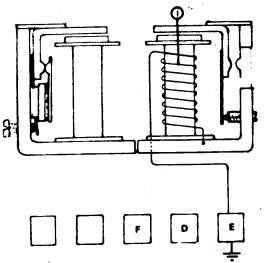

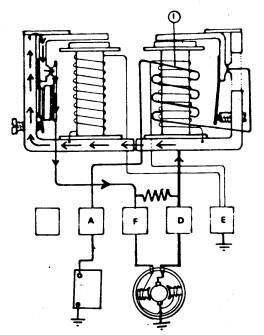

Fig. 3

The operation of the 'cut-out' (Fig. 3) is similar to that of the

regulator, except that the points are spring loaded open, and the magnetic pull

draws them together. A similar shunt Coil (Fig.

3- 1) is wound around the cut-out core with one-end connected to the frame

and the other to earth. Spring tension is set so that the points close when the

generator output is Just above nominal terminal voltage of the battery and open

again to disconnect the battery as the generator output falls.

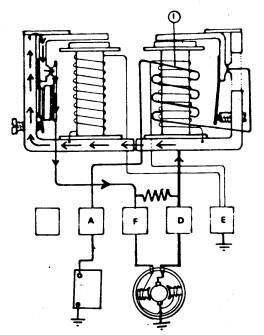

Fig. 4

Fig. 4 shows a constant

voltage control circuit where Output from the 'D' terminal goes to the

regulator frame, the cut-out points are pulled together, and current is passing

around the heavy series winding (Fig.

4 - 1) on the cut-out bobbin and on to terminal 'A' which is connected to

the battery.

The purpose of the series coil is to add strength to the shunt coil.

Once the contacts have closed, current passing to the battery along the series

winding strengthens the magnetic field and prevents the contacts 'bouncing' or

'chattering'. Also, when generator output falls below battery voltage, the

current reverses in the series winding, causing the magnetic field to collapse

quickly and open the cut-out points.

The generator voltage then builds up until it reaches the pre-set level

when the regulator points operate.

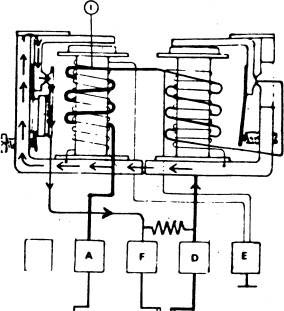

The problem that would now arise is that if the battery was in a low

state of charge, the pressure differential would be too great, and the heavy

current flow could damage the armature. To prevent this, a series coil (Fig. 5 - 1) is wound around the

regulator bobbin in the circuit from the cut-out series coil to the 'A'

terminal; this means that all the current passing from the generator to the

battery passes through these compensating turns, so adding to the magnetic

field of the shunt coil. The heavier the current, the stronger the magnetic

field and the sooner the regulator points open. This lowers the operating

voltage of the dynamo and restricts the current flow to a safe limit.

Fig. 5

As the state of charge of the battery

improves, the charging current will decrease, the series turns magnetism

decreases, and the voltage at which the contacts open will become higher, until

finally it is only limited by the shunt coil.

Any extra

load - e.g. lights, heater, wipers, etc., - must also be catered for, and extra

turns, called load turns (Fig. 6-1), may be added to the

regulator series coil and taken out to A1, which is connected to the ignition

switch, lights, and accessories fuse.

Fig. 6

Both shunt

coils consist of many turns of' fine wire, the resistance of which varies with

changes in temperature. As temperature increases, resistance increases, and

due to the reduction in current flow, magnetism will be lowered, and therefore

the voltage required to operate the contacts would increase. To counteract

this, each armature tension spring has a bi-metal strip fitted (Fig. 6- 2). these

cause the spring tension on the armature to fall as temperature rises - and so

maintain control at the specified voltage.

POSSIBLE FAULTS

Malfunction of the control box can be due to several

factors:

1. Incorrect electrical settings.

2. Oxidization of the points.

3. Incorrect air gaps.

N.B. THE REGULATOR SETTINGS SHOULD ALWAYS

BE CHECKED BEFORE DEALING WITH THE CONTACT POINTS AND

AIR GAPS.

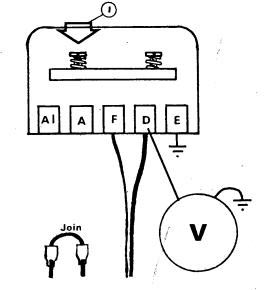

1. REGULATOR SETTINGS

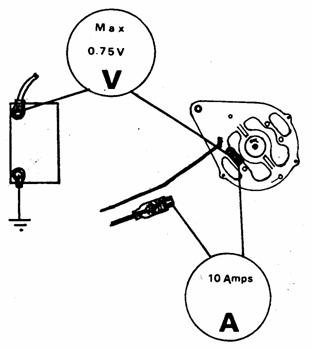

Fig. 7

Disconnect A

and A1 leads, this will disconnect the battery from the generator and take the

series windings out of circuit.

Connect a voltmeter between the regulator

frame or 'D' terminal and earth. Join the A and A1 leads to provide an ignition

feed.

Start the

engine and run up to charging speed: the voltage reading will increase until

the setting point of the regulator is reached and there should then be no

further Increase· If the voltage does not conform to specification for the

particular model, turn screw (Fig.7-1) inwards to increase the voltage, or

outwards to lower it, then re-check the reading·

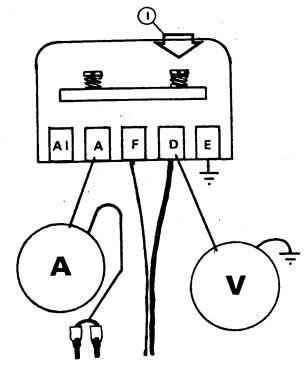

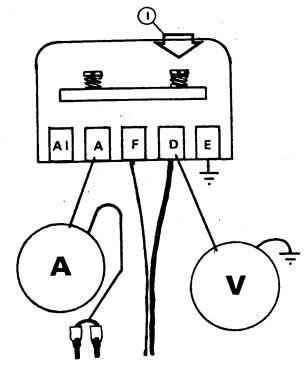

CUT-OUT

Fig.

8

We must now

check the operation of the cut-out. Leaving the voltmeter connected as before,

connect in ammeter between control box ‘A’ and the disconnected leads, Switch

on the headlamps, start engine, and slowly Increase speed. The voltage reading

will rise steadily, and when the contact points close the voltage will drop

back and then rise again. The point reached just before the drop back should be

between 12.7 and 13.3 volts.

If outside

these limits, switch off the engine, and. adjust screw (Fig. 8-1), inwards to raise the voltage,

outwards to lover it.

REVERSE CURRENT

Once the

cut-In voltage is correct, the reverse current should be checked. Leaving the

ammeter and voltmeter connected as before, and with headlamps still on, run the

engine at charging speed, ensuring that the ammeter is indicating a charge.

Watch the

ammeter carefully as you slowly reduce engine speed. The ammeter should

register a slight discharge - of approximately 2 to 5 amps before the cut-out

points open - before return to zero

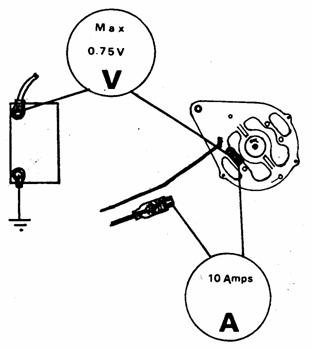

CIRCUIT VOLTAGE DROP (SUPPLY LINE)

Fig. 9

We should now

check the supply line from dynamo to battery for high resistance. Remove the

'D' lead at the dynamo, and connect the ammeter into the circuit. Start and run

engine, increasing speed until ammeter indicates 10 amps. Connect voltmeter

between ‘D’ terminal of dynamo and the battery Insulated terminal, and the

voltmeter reading should not exceed 0.75 volt.

2. OXIDISATION

OF THE POINTS

It is

Important to note that the regulator points are made of tungsten, and should be

cleaned with carborundum stone or silicon carbide paper, but the cut-out

points are made of silver, and should only be cleaned with fine glass paper.

All dust should be removed, preferably with a cloth soaked in methylated

spirit.

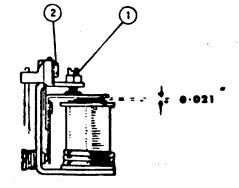

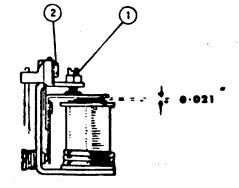

3. AIR GAP SETTING RB. I06/2

REGULATOR

Fig.10

Unscrew

the fixed contact adjustment

Unlock

armature-securing screws

Insert 0.021" feeler gauge

between armature and core face, Press armature down squarely against the gauge

and re-tighten armature fixing screws (Fig. 10-2)

Leaving gauge in position, screw the

fixed contact down until it just touches the moving contact, and tighten

locknut.

Always

reset the voltage setting after cleaning or resetting.

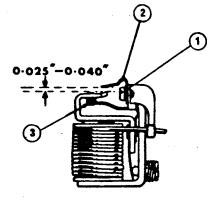

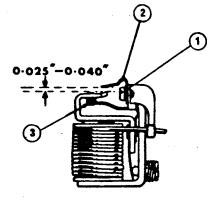

CUT-OUT

Fig. 11

Unscrew the armature securing screws

(Fig. 11-1)

Press the armature down on the core

face and re-tighten the securing screws. Bend the stop arm (Fig. 11-2)

to give a gap of 0.025" to 0.040" to the armature tongue, with the

armature held down. Release the armature and set insulated contact arm (Fig.11-3)

to give a contact "follow-through” of between 0.010” to

0.020" when armature is pressed against core face.